Test

Plywood can be used for a range of different things including everything from furniture to siding, but what exactly is it? Which kinds of tree are usually used for it and what do you need to know about this type of material before you get started?

We will try and address all the different things that you should know about the material to make sure you’re making the best possible decision in the process.

It’s very versatile in its function which is why it’s seen in so many places. It has a bunch of advantages and disadvantages when compared to other types of siding that we’ll walk you through. In a lot of instances, it can be installed by a skilled DIY person or otherwise, you can always get the help of wood siding contractors for whatever you need their help for. Want to start talking with contractors? Fill out the form below to be matched with the 4 most relevant contractors in your area. It’s a free service! (The article continues underneath the form.)

Pros and Cons of Plywood

The more information you have, the more easily you’ll be able to make the right decision.

Pros of Plywood

- Its weight – plywood is very light which makes it a material that’s easier to work with. It’s also lighter than its solid wood counterpart

- Its cost – if the alternative you’re looking at is solid wood, you’ll see that plywood is significantly more affordable.

- The strength – its composition makes it a surprisingly strong material with great performance in a lot of ways.

- Better resistance against moisture than other materials – wood siding is known for being affected by moisture if not protected properly and while a wooden material won’t be completely water-resistance, good grade plywood can provide fairly good protection.

- Aesthetics – the layer that is intended to be the outer one generally has a nicer surface than the inner layer and plywood can be made to look great. It can be painted to look better.

- Added convenience with the availability of big boards – when you’re doing a DIY project, or even if you’re getting a professional handyman to help you, the fact that you can get big panels can be very convenient and speed up the installation.

- Less risk of the wood splitting – while having the wood split at the ends is still a possibility, plywood is less likely to do so than solid wood is, especially if you’re careful in choosing the planks that you’re choosing for the project. Later on, we’ll tell you how to choose the right boards for your project.

- It’s a relatively green option – you’re doing all these other things to go green and you want to do whatever you can to make sure that your construction projects are also as eco-friendly as possible.

- The risk of shrinking and cracking is greatly reduced by its production processes.

Cons of Plywood

The material also has certain cons that you should know about and there are obviously a bunch of other alternative materials that you can choose between too.

- It’s not solid wood – if you want the traditional charm associated with wood, solid wood is the route that most people choose to go with because it simply offers more versatility in terms of the different styles available.

- OSB and MDF are both cheaper options than plywood – MDF and OSB are other wooden products turned into planks, and relative to those, plywood is the more expensive option, but it’s still an incredibly affordable option, especially when compared to other types of wood.

- Cutting plywood is difficult – since you’re basically cutting through several layers of material, the cutting process is not easy.

- Be aware of splinters – it is a type of engineered wood and you will need to keep that in mind as it means there is the possibility of splinters, especially on the ends.

- Some climates are better suited for the use of plywood than others are – while plywood does a decent job at being water-resistant, very wet climates are better suited for materials that have even greater water-resistance than any wood material does.

- Termite and pest infection can be a problem – pest infection is a problem with any kind of wooden building material. Some types of wood are more resistant than others, but wood is not the best solution for pest-resistance in general.

- If you don’t know what type of wood is used in the plywood, it’s not always easy – the type of wood used can be hard to detect in situations where you don’t know.

Types of Plywood

What you need to know is that plywood is not a one-size-fits-all, and there are a number of different things to look out for, the type of wood being used being one of them. Plywood can contain different number of plies, also known as the plies in plywood. Each panel will have no less than 3 plies.

One side of the material is usually more smooth than the other, which is the one that will be facing outwards. The other side is commonly unfinished since it won’t be seen anyway, meaning it won’t be as nice to look at either.

When you need something that holds a lot of screws, hinges and other things attached to it, you should start looking towards veneer-core. To help lessen the burden of unwanted sound or harsh weather conditions, you may be able to find insulated plywood which contains a foam rubber core. The added foam rubber core will help in terms of insulation and lower your energy bill, so it’s worth considering if the plywood is going up on an air conditioned space.

Grades

The plywood grades is determined by the front and the back of the material, since you can either get materials that are nice on one side and rough on the other or ones that are nice on both sides. A is the best grade for the front, while D is the worst. The grade of the back goes from one to for with 1 being the best. A4 therefore means it’s a grade that is nice on the face and less so on the back. The back side could have a range of defect including discoloration.

A1 is a plywood that is the best quality on both sides. The grade will be visible on the sheets. Knots and voids is what will take it from one letter grade to one grade to the next, but it also includes the amount of work that was actually being done to deal with the defects. The price of the material will also depend on the grade.

For Plywood grades A & B, large knots will are taken out and patched up in a manner that allows for good finishing and to remove the problems caused by knots. To give it either the A & B grade, the material will need to not have the need for a lot of patches to start off with and will be made from higher quality pieces of wood.

Plywood made with either C or D grades will be more affordable but you will see that there are more repairs done to these, and the repairs and associated defects can consequently end up causing different issues. If you’re simply having to use the plywood under a different type of material, these options may suffice.

Finding the Right Plywood For Your Project

When you enter a home improvement store, you’ll see that the selection of materials can be very great. You, as well as general contractors and siding contractors will be going there for the building material needs. Since it might be expensive to use grade A plywood for projects that really don’t require it, the stores need to keep a different variety for all different projects.

Plywood sheathing is what you would use for construction projects where a lot of material is needed, it won’t be seen because it will be covered, so this could be used in roofing projects, garage remodeling projects or even for functional purposes in the garage, like shelving, where aesthetics may be secondary and you simply want something that gets the job done.

Be sure to also read our post on turning a garage into a room with all the different steps it includes.

When choosing plywood for a siding project, moisture-resistance is what you will need to look for among other things. CDX is a type of sheathing that offers that feature. The biggest mistake you can make is to use plywood intended for indoor use outdoors. The distinction is significant and will be indicated clearly.

The quality of the plywood as well as the moisture level it is exposed to and the chemicals involved in the construction process will all affect the durability and integrity of the material over time. Appropriate maintenance is needed too.

Pressure-Treated Plywood

Would you go outside without a jacket if it’s freezing? Chances are you wouldn’t and the same way you need to wear a jacket in those conditions, plywood for outdoor purposes need to equally be ready for the outdoor environments.

Rain, snow, moisture and sun are constant forces working against the plywood. Because of it, you will need to find the right type of plywood for the project.

You should make sure you know that pressure-treated plywood is not necessarily the same as sheets labeled as outdoor.

Pressure-treated options will have chemicals added to it with the intention of making it more mold and insect-resistant. What that means is that it might be able to keep looking good for a long time with minimal maintenance.

CDX is a more rough surface that is commonly used when you plan on covering the material by something else at a later point. The CD in the name is the grade of the finish that we previously talked about and the X means that a glue has been used that is good for the outside. The material will, however, need additional protection at a later point. It’s also perfect for indoor uses where the finish is less important, especially if you’re concerned about saving money while still getting the project done.

Given that pressure-treated plywood has a bunch of chemicals added to it, you will need to use nails and fasteners that are made to withstand those chemicals. These nails include stainless steel ones or galvanized nails, with stainless steel ones being the more expensive option.

Things You Need to Keep in Mind When You’re Working With Plywood

Since a lot of the plywood for siding purposes contain a range of chemicals, you will need to be careful in the process of working with them. There’s both a concern when it comes to the dust, because inhaling dust is never a good thing, especially not wood dust, and it only gets worse with dust that is mixed with a bunch of toxic chemicals. The right protective mask and safety glasses is therefore important.

You should also keep the cutting of the plywood away from the house to keep the dust from going into the house.

The glue that is used for plywood is also a cause for concern according to some consumer advocate groups. An “E” rating on the plywood will mean that the glue used is a low formaldehyde-emitting type.

Oriented Strand Board (OSB board) vs Plywood

With the question of whether OSB or plywood is better, the Family Handyman magazine decided to try and lower the edges in water and the OSB swelled a lot compared to the plywood, so if you’re living in an area with a lot of moisture, OSB is definitely not as good of an option as plywood.

If you’re simply using it for a project that won’t be exposed to any moisture, OSB could be a better option since it’s cheaper and a lot of different associations say that they have the same strength and durability when not exposed to moisture. OSB is a popular material for things such as floor and roof sheating because of it, but it’s also extremely important that roof leaks are fixed to keep it from deteriorating.

The video below shows why OSB should not be used for siding.

Plywood Sizes

When going to the home improvement store, the most common sizes for plywood is 4 feet by 8 feet. The sheets can also commonly be found 10 foot long or 12 foot. Smaller sheets will usually be sold as 2′ by 4′.

Plywood Thickness

The more plies you add to the plywood, the thicker the material will inevitably going to end up being, and when you go to buy it, the nominal thickness is indicated, meaning the actual thickness might be slightly different, usually being 1/32″ thinner than what is indicated.

The typical thicknesses sold include 1/4″, 1/2″ and 3/4″ in nominal thickness but the actual thing being just slightly thinner. What that means is that the boards might in fact rather be 7/32″, 15/32″ or 23/32″. It typically won’t cause a lot of problems for things such as siding since it’s more rough than other fine carpentry projects that could include cabinets. For other purposes those discrepancies could cause things to be loose as a consequence.

While a piece of plywood may have started out 1/2″ in thickness, the drying would could be the reason that the thickness ends up a little bit different. The manufacturing tolerances also cause some of the discrepancy, and while it might not be convenient for your project if you’re making kitchen cabinets, there’s no easy solution.

For things such as subflooring, additional support is needed so you will need thicker options.

Types of Exterior Plywood

CDX is porbably the more common type of plywood for exterior purposes, conveniently available in different thicknesses depending on your project. While CDX is commonly used outside, ABX, ACX or BCX are also outdoor options, again having the letters indicating the quality. ABX is the more expensive option.

Marine grade is another plywood made to withstand the test of time outside. The core is made up of knot-free sheets and water won’t get stuck as a consequence in the middle.

We already mentioned pressure-treated plywood in its own section, and this is normally a little green in its appearance because of the chemicals that go into it.

Again, OSB can be used for exterior purposes but even if it has water-resistant glue added to it, it will start showing serious signs of damage over time when water gets to it.

For siding, T1-11 is used. It can be made with tongue and groove and it lets the homeowner change its appearance with the use of either stain or paint to achieve the desired look.

CDX is the most economical decision for outdoor uses if you want to avoid OSB. CDX can be finished with urethane, urethane also being used on wooden floors, to provide additional protection. Sheds and other things meant to look nice will best benefit from the use of T1-11, while other materials requiring water-resistance will be made from marine grade.

MDF vs Plywood

What exactly is MDF and why are people asking about this material vs plywood? Well, we’ve been asked the question enough times that we think it warrants being included in this article with a section where the two materials are compared.

The different materials both have pros and cons making them better or worse depending on the type of project you want to use it for.

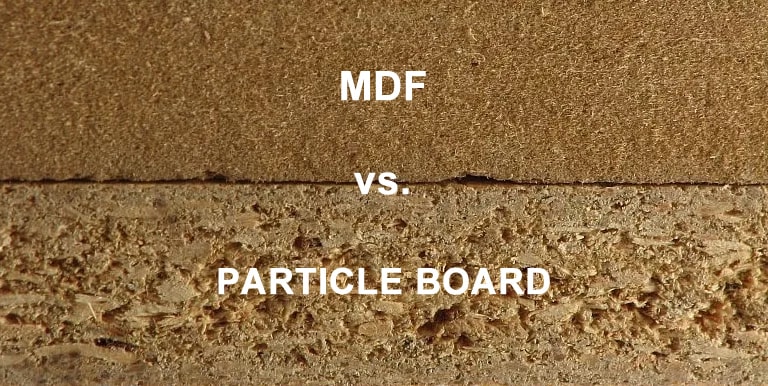

To start off with, MDF stands for Medium Density Fiberboard. It’s an engineered composite product which is comparable but denser than particle board.

As you can see from the image above, MDF is clearly denser than particle board.

Wooden fibers are mixed with binders and pressed so that they’re turned into the MDF sheets. That is the simple explanation as to how it’s made. If you want the longer explanation, you should consider checking out the video below.

MDF is available in different thicknesses depending on the purpose.

MDF’s Advantages Compared to Plywood

- Easier to cut than plywood – MDF is smoother than plywood and it helps make it easier to cut too, meaning when you need something with great details, MDF could be your preferred choice.

- Decorative edges can be made – again, smoother, it allows for decorative edges, which are very hard to make with plywood.

- Less splintering when cutting it – cutting plywood is harder and it will leave splinters at the edge.

- Easy painting – MDF can easily be painted after a primer has been applied to it.

- Knots are not a concern – with plywood, you will need to worry about knots in the sheets. That’s not the case with MDF.

- MDF is cheaper – we already mentioned it, but it’s worth mentioning again.

Disadvantages of MDF Compared to Plywood

- MDF and plywood both contain VOCs – while it’s not something that makes MDF better than plywood, it’s worth knowing that both options aren’t great in terms of VOCs. With good protection, it will be less of an issue.

- Staining is not possible with MDF – while it can be painted, it can’t be stained. It simply soaks up whatever liquid is added to it, which is a problem if you wish to stain rather than paint.

- MDF is heavy – its density makes it heavy, something that’s not an issue with plywood.

- Screws hold better with plywood – it basically just consists of fine particles and screws and nails won’t do well because of it.

- It swells and sucks up water – it’s made basically like a particle board and it’s the least water-resistant option you can go with, which is why it’s not used for siding. It’s inability to fare well with screws also makes it a bad material for siding.

Plywood Siding Types

While there are different grades and manufacturing processes that are being used, there are also different types of wood that can be used for the plywood. The process used will make the material more or less water-resistant, and the processes associated with marine grade material will obviously be far superior in terms of withstanding exposure to water, which is why it’s used for boats.

The most common types of wood used for exterior purposes include:

- Maple – this type of wood provides a very nice finishing look.

- Oak – insects and fungi have a hard time against this type of wood because it’s so tough.

- Birch – while being a strong material, temperature changes is problematic and other types of material are used in combination with it to provide the desired functionality.

- Douglas fir – it’s a pretty sturdy option to go with.

- Mahogany – when used, it’s used for cabinets and furniture typically given its visual appeal.

- Spruce – a strong material even if it’s cut very thin.

- Pine – common and a very basic option that you can go with. When this is chosen, make sure that you select the right grade.

Hardwood options are more durable than softwood. Softwood normally including cedar, spruce, redwood, pine, and fir.

Other Types of Wooden Siding

While T1-11 is the common option for plywood siding, you can also choose to use common wood for siding, and we want to walk you through the options available to you.

- Charred wood siding – it has a couple of different names it goes by, including its original Japanese name, Shou Sugi Ban. The finish adds weather-resistance and makes it more durable. It’s a very distinctive type of siding that will go unmatched in your neighborhood. When you want to make a statement, this could be it.

- Spruce – this material does not provide great protection against insects such as termites.

- Fir – a popular softwood, available in long boards which can be convenient for a seemingly seamless installation. Painting or staining will be needed to provide additional protection, and regular inspection is important. Its inability to resist the tempting moisture makes it important to get quality grade.

- Cypress – a lot of the cypress material comes from old homes, making it a green option to go with since the wood has already been harvested and you’re just giving it new life. It provides better protection against insects but it’s not a cheap option.

- Redwood – it’s great in terms of water-resistance but it’s not cheap and it can be stained or painted to achieve your desired look. It warps less than alternative wood siding choices. Make sure that you study the recommendations provided by the manufacturer to give it the maintenance it deserves.

- Cedar – great moisture-resistance while still being relatively affordable. It also provides great protection against swelling and splitting.

This article has hopefully given you a better understanding of how to ensure that your plywood siding project (T1-11!) becomes a success. Remember, you can always get additional help if you need it.